Delivering Last-Inch Logistics

Nailing down the final inches of a delivery can be complex. Fortunately, a variety of solutions show promise to help shippers navigate that crucial leg.

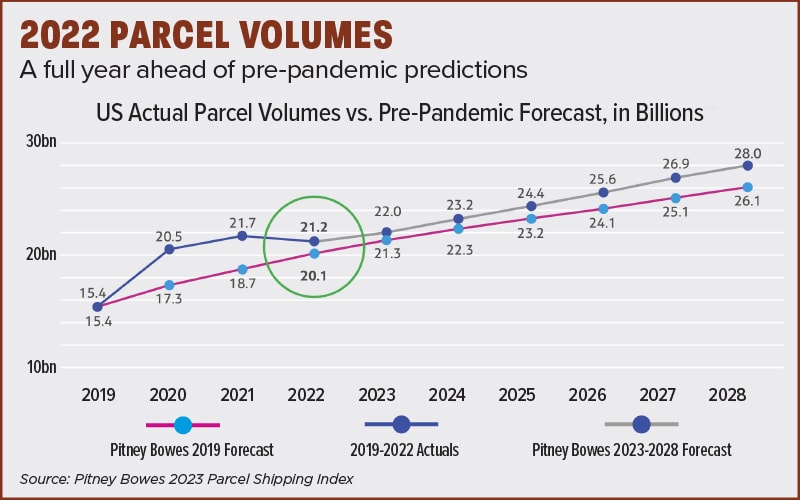

Every second of every day in 2022, 674 parcels were generated in the United States, or about 21.2 billion for the year, Pitney Bowes reports.

Ensuring those packages get to the right recipients, safely and on time, presents numerous logistics challenges. And the challenges often get dicier, as well as pricier, toward the end of each delivery.

The final mile of a parcel delivery can account for more than half—53%—of total shipping costs. While a similar statistic doesn’t appear to exist for the final inch of deliveries, it’s likely this step also accounts for a substantial portion of logistics expense.

Navigating the final inches of a delivery often becomes a complex endeavor. Drivers trying to access parking spots and buildings often find much of the territory unmapped, says Anne Goodchild, professor of civil and environmental engineering and founding director of the Urban Freight Lab at the University of Washington. The Lab coined the term “final 50 feet” to refer to the actual delivery of goods.

Among the questions drivers might need to answer, often while in traffic, are these: which door should be used if a building has several entrances? Where is the nearest parking space to the correct door? Adding to the challenges is the fact that many of these spaces, like sidewalks, are shared with others.

Figuring out how best to traverse the last step of a delivery is both challenging and increasingly necessary, as more consumers rely on home delivery, whether to help them manage busy schedules or because it’s difficult for them to get out, even to access necessities such as food or medicine, says Melissa Twiningdavis, senior managing director, supply chain operations at Accenture.

A Dose of Medical Deliveries

While discussions about last mile often focus on deliveries of consumer goods, delivery of medical items is poised to skyrocket. The prescription delivery services market, for instance, will grow by 17.8% annually through 2030, predicts Future Marketing Insights. These deliveries often bring even more complexity to the final inch, as they require temperature and other controls.

A number of solutions show promise for helping shippers navigate the last inch of deliveries. They include software to more efficiently route delivery vehicles, community lockers, cargo bikes, crowdsourced delivery models, and the use of brick-and-mortar retail stores. Even drones are being piloted in a few areas.

“We’ll see a lot of creativity and innovation in this space in the coming years,” says Gary Nemmers, chief executive officer with Magaya, a logistics software provider.

Final Inch Challenges

Congestion makes deliveries in urban areas tricky and time consuming. Delivery vehicles and trucks spent 28% of their trip time cruising for parking in downtown Seattle, according to a recent study by Goodchild and Giacomo Dalla Chiara, research associate, at the University of Washington.

Porch piracy, or package theft, is another concern. In 2022, about 260 million packages disappeared from porches and front doors across the United States, reports Safewise, an online resource providing safety tools and information.

Consumers increasingly expect visibility to the changing status of their orders, from when it’s picked, to when it heads to a distribution center, and when it arrives at their front door, says Jeremy Tancredi, partner in the operations excellence line with West Monroe, a digital services firm.

As the value of the delivery increases, so do expectations. Many consumers want to know the delivery time and then see a picture of the package near their front door.

It’s not only consumers who are looking for this information. All constituents involved in a transaction, such as distributors and retailers, want “one version of the truth,” says Jeff Abeson, vice president with Ryder Supply Chain Solutions. “It’s a huge challenge.”

Despite the challenges, the customer experience is “paramount,” when it comes to executing the final inch, says Nathan Lease, senior director, logistics research and advisory with Gartner. It’s often online customers’ primary interaction with a brand.

Even as many consumers want rapid delivery, they’re also considering the environmental impact of their delivery choices. Some firms now offer multiple shipment options, and show the carbon impact of each.

Final Inch Solutions

A growing range of technology solutions is available to help shippers meet these challenges. They tend to be at different points of maturity, and it’s not clear any are perfected.

“We’re in a phase of experimentation and ideas,” Goodchild says. Rather than look for a single “best idea,” it’s likely different solutions will apply in different scenarios.

So, a shipper may use a parcel company to reach suburban customers, and then lockers and cargo bikes when delivering in an urban center.

Here is a look at some of the most promising solutions.

Route-Optimizing Software

Investments made in artificial intelligence (AI) technology can optimize routes to both conserve fuel and minimize mileage and wear on delivery fleets, explains Raj Vaughn-Patel, manager and SAP retail lead with Clarkston Consulting.

The ability to help shippers save time and money is helping to drive the market for route optimization software, which is expected to grow by nearly 11% annually, according to a Research and Markets report.

Delivery Robots

While they may look like something from a futuristic film, delivery robots that can take packages from a vehicle to the doorstep are already in use.

For example, Starship Technologies’ autonomous robots have made more than five million deliveries to date, according to the San Francisco-based company. Sensors and one dozen cameras allow each robot to see where it’s going and navigate around people and objects. Each robot is tracked with GPS to within one inch, and can be unlocked only with the customer’s phone.

Drones

Drone delivery has been talked about for years, but hasn’t really taken off. “The technology has been more than capable for quite a while,” says Ryan Walsh, founder and CEO with Valqari, which makes drone landing stations, among other products. Valqari’s stations have been deployed in golf courses, stadiums, and campuses.

What has lagged are regulations, Walsh says. With limited exceptions, most drones in the United States currently must fly within the pilot’s line of sight. That eliminates a good portion of the market.

However, a few drones are in operation. In mid-2022, Amazon announced it would begin drone deliveries in Lockeford, California, and College Station, Texas. More recently, Amazon launched the next generation of its drones.

In February 2023, Senator Mark Warner (D.VA) introduced the Increasing Competitiveness for American Drones Act of 2023, which has gained bipartisan support. Among other provisions, the bill requires the Federal Aviation Administration to establish a regulatory pathway for certification or approval of unmanned aircraft systems to enable commercial operations that are beyond visual line of sight.

Drones tend to make the most sense as the delivery distance increases, Walsh says. For example, it’s likely more efficient to have a drone deliver a burger to a consumer who’s five miles away, than to have the consumer drive to get it.

Valqari’s landing station technology precisely aligns packages and drones, allowing for reliable package loading and unloading regardless of where the drone places the payload.

Locker systems

While lockers are not new technology, they’re starting to be deployed in new ways to help with the last inch of delivery. Lockers “separate the customer from the carrier, but in a secure way,” Goodchild says.

What’s less clear is how much demand exists for lockers. As Abeson notes, if a consumer can order online and receive their shipment in one or two days, or get it at the store—to which they may already be going—how much benefit do lockers add?

Lockers tend to be most useful when they’re located near where people are biking, bussing, or walking, says Spencer Shute, principal consultant with Proxima, a supply chain consulting firm. Then, they can stop by the lockers when they’re already out and about.

What about lockers at consumers’ homes? “We’ve seen a lot of misses about what a porch locker can look like,” Twiningdavis says.

However, the idea might come back around. Software already exists that allows some drivers to open the boxes by scanning a QR code. The main hurdle is cost, as the boxes operating the software cost several hundred dollars.

Crowdsourced delivery

Crowdsourced delivery models, which use networks of local, non-professional couriers to deliver packages to customers’ doors, are often associated with meal delivery services such as Doordash. They are now branching into other areas.

One driver behind the interest in crowdsourced package delivery is the way it solves for a lot of the final-inch challenges retailers face, such as cost and the environmental impact of deliveries. It also offers flexibility.

The downside? “Companies can lose control of their brand,” Abeson says.

If a company is going to engage a third-party delivery company, a few steps can make the partnership more productive.

“Do proper sourcing selection and due diligence, as it’s a critical touch point with your customer,” says Ben YoKell, managing director with Grant Thornton.

A number of agencies have rushed into the market, and not all are fiscally prudent or financially stable, and it’s such a new market that it can be hard to find records. Proper vetting is critical.

It’s also important to consider technology integration with your third-party providers and couriers, so you can provide customers with tracking and other information.

“It’s reasonable to expect that your external providers can integrate to provide visibility,” YoKell says.

Cargo Bikes

In congested urban areas, cargo bikes can help streamline deliveries.

A study from the European Transport Research Review found cargo bikes to be more cost effective than delivery trucks in some cases, including delivery routes that were less than about two miles from a distribution center, with 50 parcels per stop, and with a high density of residential units and low delivery volumes per stop.

Since 2009, B-Line has provided cycle logistics services in Portland, Oregon, through its colorful cargo trikes. The company’s fleet of about one dozen trikes often transports food and beverages from growers and manufacturers to the city’s restaurants.

“This way, a produce company doesn’t have to take 53-foot trailer into the urban core,” says Franklin Jones, founder and chief executive officer of B-Line.

Instead, the company can bring its products to B-Line’s urban consolidation center, where employees break down the pallets and deliver them to restaurants, bodegas, and grocery stores, along with some front porch delivery for CSA (consumer supported agriculture) and similar programs.

Since the trikes traverse within a four-mile radius, they’re often able to criss-cross deliveries. So, a bike might deliver produce to several restaurants, head to the bakery next door, pick up bread, and deliver that to several other restaurants.

The typical trike completes between three to five routes daily and can carry up to 600 pounds at a time. B-Line also does a notable volume of parcel deliveries from office supply stores.

B-Line’s trike and truck delivery system enables fast deliveries to local accounts, ranging from restaurants to regional retailers.

Leveraging Physical Stores

As part of their efforts to tackle last-inch shipping challenges, some shippers are turning to physical stores.

“We are seeing retailers more creatively leverage their existing brick-and-mortar presence to optimize the fulfillment of orders for deliveries, reduce the total distance the deliveries need to travel to the customer, and save on fuel costs,” says Vaughn-Patel.

In effect, stores are “starting to act like mini distribution centers,” Shute says. This works particularly well when the fulfillment center is one or two days from the store, as the store can then hold products closer to customers.

Some shippers even are tapping other retailers’ physical store infrastructure. Amazon, for instance, has partnered with retailers, including PacSun and GNC, to offer same-day delivery in some cities.

Delivering A Seamless Experience

It’s likely that multiple solutions will continue to help shippers tackle the challenges of the final inch. The optimal solution for a specific delivery likely will depend on the size and type of product and the delivery location.

No matter which solutions a shipper uses, the goal is “a completely seamless consumer experience between social, mobile, digital, and physical,” YoKell says.

At the same time, retailers will get smarter about pricing these services accordingly. “The market is willing to pay to get what they want, if they get what they want,” YoKell adds.

What is the Final Inch?

How do you define the “final inch”? The experts weigh in:

“It’s getting the shipment to the final customer,” says Spencer Shute of Proxima. This won’t necessarily be through a distribution network, but could be through third-party carriers or other solutions.

“It’s the actual package hand off,” says Jeremy Tancredi, partner with West Monroe, noting that it’s enough to get it to the front porch.

The final inch means “the delivery is in your hands,” says Melissa Twiningdavis of Accenture.

It’s “delivering a package to an end customer conveniently, efficiently, and safely,” says Raj Vaughn-Patel of Clarkston Consulting. This includes value-added services, like signature capture or identity verification that are promised as part of the delivery service, he says.