No Place for Technophobes: Technologies Streamline Global Trade

They used to be just trendy buzzwords, but artificial intelligence (AI) and blockchain are now poised to have a transformative impact on global supply chain management. If you’ve been shying away from these technologies, it may be time to consider their potential.

It is a widely shared sentiment: “Technology is great…when it works.” Controlled enthusiasm about constantly evolving technology resonates with business professionals of all stripes, but supply chain experts agree that there is no room for technophobia in today’s logistics space. Logistics providers who are laggards in adopting new technologies run the risk of paying a serious competitive price, while early adopters of technologies that accelerate and improve supply chain performance race to the top.

Artificial intelligence (AI) and blockchain are two technologies that are quickly becoming indispensable tools within the global supply chain sector.

Artificial intelligence, with its ability to analyze vast datasets and forecast trends, helps to enable the proactive decision-making needed to optimize logistics, predict demand, and enhance overall efficiency. Its role in predictive analytics, route optimization, and demand forecasting has become paramount in addressing the complexities of global trade.

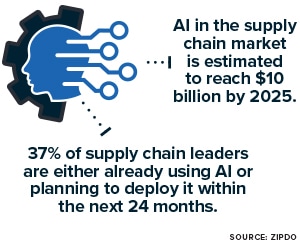

Today, 37% of supply chain leaders are currently using AI or are planning to deploy it within the next 24 months, according to data compiled by zipdo. The market for AI in the supply chain is expected to hit $10 billion by 2025.

Blockchain technology promotes transparency, traceability, and security by creating an immutable ledger of transactions across the supply chain network. This decentralized and tamper-resistant system goes a long way toward instilling trust among stakeholders, while it streamlines documentation and significantly reduces the risk of fraud.

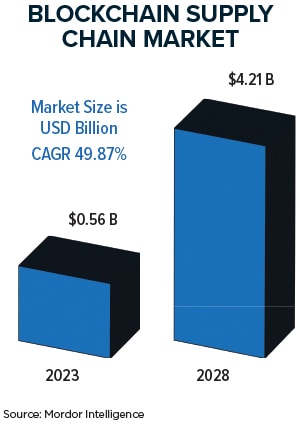

Blockchain is still a nascent force in the supply chain, but its supply chain market size is expected to grow from $0.56 billion in 2023 to $4.21 billion by 2028, at a CAGR of 49.87%, according to Mordor Intelligence.

Together, AI and blockchain are drastically altering how companies manage, secure, and optimize operations within the intricate web of global supply chains and trade networks. Here’s a closer look at some companies that create, produce, and use these advanced tools.

ARTIFICIAL INTELLIGENCE: A Better Way to Analyze Data

Global household appliance brand Dyson uses an AI- and automation-based technology that aggregates and contextualizes data to help make more effective supply chain, procurement, and product decisions. The solution also enhances visibility and collaboration.

A lack of information visibility and collaboration across its procurement, supply chain, and product engineering teams was causing issues for Dyson, a multinational provider of household appliances such as vacuum cleaners, fans, air purifiers, and other items. The company needed a better way to analyze data across departments—and a fresh mindset around embracing AI.

“It’s fantastic to have a system that can analyze the data and give you insights, but you won’t go anywhere if your mindset is still stuck on spreadsheets,” says Michelle Shi-Verdaasdonk, chief supply chain officer at Dyson.

The solution came from LevaData’s proprietary AI- and automation-based technology that aggregates and contextualizes data to help supply chain, procurement, and product teams make better decisions faster. The company’s solution helps sourcing teams reduce costs and mitigate risk at the part, ingredient, and metal level, arming procurement teams with built-in capabilities that provide improved visibility and increased collaboration.

The end game? A greater ability to take decisive actions.

“LevaData is equipping teams with the insights and intelligence they need to execute with higher velocity and greater accuracy,” says Keith Hartley, CEO of LevaData.

By contextualizing complex data from hundreds of data sets, the LevaData platform provides actionable insights and potential cost-savings opportunities to companies like Dyson that are looking to gain a competitive edge. The platform’s custom dashboards provide spend intelligence using real-time data and interactive visualizations, which “can dramatically accelerate decision-making,” Hartley notes.

Probabilistic Planning is the Right Tool

Seeking efficiencies on its path to business growth and network expansion, Grupo Mercury, a Latin American importer and marketer of wholesale electronics products, went searching for an AI partner. It selected an AI-driven planning suite called Service Optimizer 99+ (SO99+) from ToolsGroup, a global retail and supply chain planning and optimization software provider.

Seeking efficiencies on its path to business growth and network expansion, Grupo Mercury, a Latin American importer and marketer of wholesale electronics products, went searching for an AI partner. It selected an AI-driven planning suite called Service Optimizer 99+ (SO99+) from ToolsGroup, a global retail and supply chain planning and optimization software provider.

SO99+ is an AI-fueled supply chain planning tool that helps retailers, distributors, and manufacturers improve the resilience and performance of their operations. Its effectiveness comes from a probabilistic planning approach that leverages AI and real-time data from across the enterprise for fast decision making. The solution accounts for variability and tailors inventory to demand, helping to mitigate risk and uncertainty in demand and supply planning.

By leveraging ToolsGroup’s native AI and automation, Grupo Mercury says it can navigate complexity, satisfy demand, and achieve enhanced business performance amid network expansion.

“We chose ToolsGroup to accompany us on this journey because the company had the maturity to support our expansion plan, an in-depth understanding of the Latin American marketplace, and a track record of handling similar challenges and product types efficiently and profitably,” says Fredy Martinez, regional director of supply chain for Grupo Mercury.

By working closely with Grupo Mercury, ToolsGroup can “build a more resilient supply chain that will help them convert growth potential into real-world benefits,” says Inna Kuznetsova, CEO of ToolsGroup.

Microsoft Serves as an AI Copilot

Georg Glantschnig, Vice President, Dynamics 365, Microsoft

Microsoft has long provided supply chain management solutions. Its Dynamics 365 Supply Chain Management suite offers a unified view of inventory, manufacturing, service, and logistics functions, and uses predictive analytics to turn data into insights that support strategic decision-making.

The company’s newer, AI-powered user experience is known as Copilot for Dynamics 365 Supply Chain Management. Microsoft introduced Copilot capabilities that enable procurement teams to handle purchase order changes in a scalable, efficient manner and assess the impact of those changes downstream to production and distribution.

Microsoft’s AI tool also offers natural language-based conversational help and guidance on next best actions within workflows to improve productivity, collaboration, and performance.

For example, users no longer need to leave their workspace or toggle between multiple tabs to act on insights. These capabilities enable supply chain teams to mitigate potential disruptions rapidly.

Most importantly, Microsoft says, it will guide teams on how to execute with step-by-step conversational help and enhance their user experience.

“Generative AI and Microsoft Copilot have opened the door for us to reimagine how workers and employees engage with their everyday tools and workflows,” says Georg Glantschnig, vice president of the Dynamics 365 ERP portfolio at Microsoft.

“Empowering supply chain workers is no longer just about building new workspaces to work from—like control towers or command centers—but rather about how we surface relevant information and enable quicker decision-making in the flow of work,” Glantschnig says.

BLOCKCHAIN: Blockchain as Digital Provenance?

Measured by financial assets under administration, Provenance is the largest public blockchain in the world. Created in 2018, the open source blockchain is part of the Cosmos ecosystem and is designed for the regulated financial services industry.

Measured by financial assets under administration, Provenance is the largest public blockchain in the world. Created in 2018, the open source blockchain is part of the Cosmos ecosystem and is designed for the regulated financial services industry.

The Provenance Blockchain Foundation supports the development and growth of Provenance Blockchain, working to steer the blockchain toward developing, enabling, and securing a robust environment for global digital financial-asset use cases.

“Trade finance, which traditionally relies on paper or outdated centralized infrastructure, remains a constant thorn in the side of a rapidly changing and complex global trade sector,” explains Dan Garzia, CMO of the Provenance Blockchain Foundation.

By contrast, he says, blockchain technology enables immutable transparency, which reduces administrative overhead and settlement times through elements such as smart contracts and Markers (smart contract capabilities engineered directly into the blockchain protocol), and offers real-time tracking.

Public blockchains such as Provenance offer benefits for data privacy and data security, as well, including decentralization (improving data’s resistance to hacking and data breaches), transparency (improving audits and data tracking), and cryptography (protecting data from being accessed or altered without permission).

Healthcare providers, for example, can better manage patient records and clinical trials data securely and privately.

One company succeeding with Provenance is ZorroSign, a global provider of data security solutions built on blockchain—including a digital signature solution that allows users to sign security documents online. The company recently announced its advanced integration with Provenance.

End-to-End Traceability for the Win

When VeChain Technology launched in 2015, it was rare to see major business applications running on public blockchains, and the company acknowledges that the level of enthusiasm was low.

However, VeChain’s leadership team endeavored to raise acceptance by differentiating the company from the many speculative crypto projects in the marketplace and saw the opportunity for enterprises to capitalize on blockchain even beyond the digital realm.

One strategy was to offer end-to-end traceability. VeChain’s blockchain platform enables an ongoing view of all transactions among supply chain participants.

“Blockchain technology continues to disrupt the supply chain,” says Kuan Thurow, assistant vice president, VeChain US, Inc. “Decentralization, an important trait of public blockchains, provides a trust mechanism. It makes data more robust and reliable when managing multiple competing stakeholders.

“Record-keeping, compliance, and dispute management are several ways blockchain can ensure product quality throughout the supply chain,” Thurow adds.

In 2022, VeChain entered into a strategic integration partnership with TruTrace Technologies, developer of a fully integrated blockchain platform for the cannabis, food, apparel, and pharmaceutical industries. The direct connection between the companies allows TruTrace to offer a seamless way to utilize blockchain without large investments in network infrastructure or management of cryptocurrencies.

Shoppers Drug Mart, Canada’s largest retail pharmacy chain, currently uses TruTrace’s platform as its underpinning technology infrastructure for traceability and accountability associated with its medical cannabis program.

“When we began the development of TruTrace, our mission was to serve as an interconnected blockchain-secured product registry and traceability solution that could bring all stakeholders together and track and manage variabilities from batch to batch and lot to lot,” says Robert Galarza, CEO of TruTrace.

Early on, they encountered difficulties using this technology, including onerous transaction fees and being limited to permission-based systems. VeChain’s solution helped TruTrace get back on track. The company now has “a true enterprise-grade blockchain that understands how to bring value to clients at a reasonable cost with the ability to scale at a global level,” Galarza says.

Decentralizing the Chain

An IoT-enabled device that can recognize when a load arrives, send an update that triggers an invoice, and facilitates payment automatically used to sound too good to be true. But today it’s available through the use of blockchain networks such as Chainlink, a decentralized blockchain oracle network built on Ethereum.

The Chainlink platform provides a suite of services connecting global trade systems with one another and to real-world data in a reliable, secure, and decentralized manner.

Chainlink Cross-Chain Interoperability Protocol (CCIP) provides a universal interoperability standard that securely connects data and value to both legacy and blockchain systems and enables interoperability between them.

“The exchange of trade data and the verification of the movement of goods along supply chains is impeded by a fragmented trade ecosystem, where isolated systems lack access to critical information and interoperability with other systems,” says Chirag Dhull, head of product and industry marketing, Chainlink Labs.

Changing the Game

Blockchain changes all of that. “Additionally, Chainlink Functions [an additional offering from Chainlink] can be used to fetch data from any API, trigger events, and secure trade finance operations,” Dhull says.

Ultimately, Dhull says, Chainlink can increase the transparency of supply chains, reduce administrative costs, enhance materials traceability, expand trade access to emerging markets, and establish high-integrity supply chains with end-to-end verification.

That combination was appealing to global telecommunications provider Vodafone, which recently announced a collaboration with Chainlink, as well as Sumitomo Corporation and InnoWave, to address longstanding challenges in the $32-trillion global trade ecosystem.

“The integration of IoT and blockchains has the potential to provide new monetization opportunities for IoT devices,” says David Palmer, chief product officer for Vodafone’s Digital Asset Broker (DAB).

“Three billion IoT devices are forecast to be transacting in the economy of things by 2030. Securing consensus and validation between DAB and Chainlink will be important to drive this growth,” he adds.

As is becoming increasingly clear, the time is ripe for companies to embrace new technologies that help streamline, strengthen, and secure global supply chains.

Technophobes be warned: proceed at your own risk.

SPOTLIGHT ON GLOBAL TRADE MANAGEMENT

While not as buzzy as next-gen tools like AI and blockchain, global trade management (GTM) systems—arguably the workhorse of global supply chain software—still play a vital role in the supply chain tech stack of many global firms. Thanks to its ability to enable agile and compliant performance in the face of fluctuating trade regulations and increasing penalties for non-compliance, companies can use GTM systems to automate international trade management processes to mitigate risks, ensure compliance, and minimize costs. Here are two examples of GTM in action.

Opening Up Partnership Opportunities

Companies engaging in global trade want to be confident that they are in compliance with a variety of global regulations and protected from potential risks that pop up across the global supply chain. Those needs have driven some 400,000 manufacturing, logistics, channel, and distribution partners to connect on the SaaS-based global trade application suite from e2open.

The company’s cloud-native global platform enables these partners to operate as one multi-enterprise network tracking more than 12 billion transactions annually. The platform is designed to anticipate disruptions and provide opportunities to help companies improve efficiency, reduce waste, and operate sustainably.

The software is backed by a comprehensive database and business rules covering 98% of world trade. It can automatically apply regulatory rules to all cross-border transactions, helping organizations mitigate non-compliance risks such as border clearance delays, fines, loss of trade privileges, and criminal liability. Organizations also gain the ability to minimize duty costs and speed imports and exports by accessing the connections in e2open’s network of global trade partners.

Fast and Easy Filing

Filing documents required by U.S. Customs is standard fare for organizations involved in global trade. The process, however, can be anything but cut and dry—especially at scale. That challenge became evident for many ecommerce companies when Customs implemented a program (Section 321, 19 USC 1321) related to de minimis value shipments. (De minimis allows articles to be imported free of duty and import taxes when the aggregate fair retail value of the articles imported by one person on one day does not exceed $800.)

With the implementation of Section 321, many ecommerce companies took advantage of the program by fulfilling de minimis orders overseas through partnerships with international freight forwarders. The international freight forwarders were also freight consolidators who would package and sort each individual shipment into totes and load those totes into 40- or 45-foot containers so that when they arrived in the United States, the individual totes could be dropped off at a last-mile courier.

However, for an importer to take advantage of the program and avoid paying duties, they have to file three entries with Customs. Most ecommerce companies ship tens of thousands of shipments per container. In an example of 15,000 shipments in a single container, this would mean 45,000 filings, notes Darrell Ortiz, founder and CEO of CDM Software Solutions, a Customs-certified software application provider that helps carriers, NVOCCs (non-vessel operating common carriers), shippers, and importers facilitate export and import shipments into and out of the United States.

GTM solutions like CDM’s play a key role in helping companies with these cumbersome processes. “By automating the process of filing certain documents required by Customs, CDM’s Global Shipment Compliance solution has improved the efficiency of filing those documents by 90%,” says Ortiz.

CDM Software Solutions created a single-message format that enables importers to provide all the data elements for each of the three required customs filings. CDM’s internal system processes the message and sends the data to the appropriate Customs system and returns the appropriate acceptance or rejection response back to the importer. This streamlines the process and empowers companies to benefit from smart global trade strategies.